The Ultimate Guide to Choosing the Best CNC Router Bits for Woodworking

In the world of woodworking, CNC router bits are the unsung heroes that bring designs to life with precision and elegance. Selecting the best CNC router bits for wood is crucial for anyone looking to achieve high-quality finishes, whether you're a hobbyist or a seasoned professional. These bits are designed specifically to handle the challenges of wood, providing control, precision, and durability. Knowing which bits to use can make a remarkable difference in your woodworking projects, helping you achieve smoother cuts, cleaner finishes, and faster production times.

When selecting CNC router bits, there are a few key factors to consider: the bit type, material, size, and specific purpose of the cut. The vast variety of CNC bits available can make the selection process daunting, but focusing on these aspects can simplify your decision.

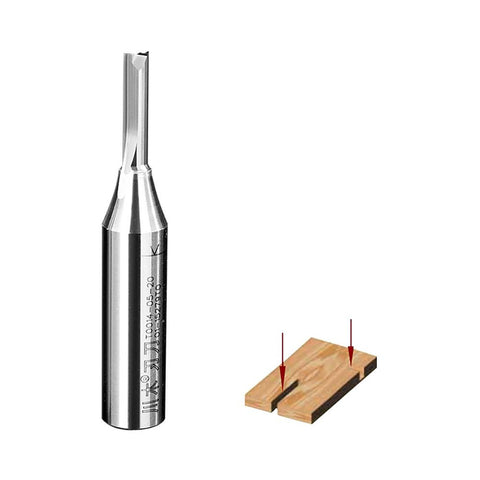

Router bits come in a wide range of shapes, each serving a specific function. Some of the most popular types include straight bits, V-groove bits, up-cut and down-cut spiral bits, ball nose bits, and flush-trim bits. Straight bits are among the most common and versatile bits used for cutting straight edges, creating dados, and making simple grooves. Their straightforward design makes them easy to use, but their effectiveness varies depending on the quality of the bit and the type of wood being cut.

V-groove bits, on the other hand, are ideal for engraving and creating intricate designs. Their V-shaped cutting profile allows for deep, clean grooves, making them perfect for decorative work and sign making. With V-groove bits, the angle of the tip is an important factor, as it influences the depth and width of the cut.

Spiral bits, which come in up-cut and down-cut varieties, are designed for more specialized work. Up-cut spiral bits are fantastic for pulling chips up and out of the material, which prevents the bit from getting clogged and allows for faster cuts. However, up-cut bits can sometimes tear out the wood fibers on the surface, so they're best suited for projects where the cut edges won't be visible. Down-cut bits, on the other hand, push chips downward, compressing the wood fibers and creating a smoother surface. These are ideal for fine work, especially on materials that tend to splinter easily.

Ball nose bits are another must-have for any CNC woodworker. They have a rounded end, making them perfect for creating rounded grooves and contours. Their shape allows them to glide smoothly over the wood, and they're often used in 3D carving projects where smooth transitions between depths are necessary. If you're looking to create flowing, organic shapes, a ball nose bit is likely your best choice.

The material of the bit also plays a crucial role in its performance and lifespan. Carbide-tipped bits are the most popular choice for woodworking, as they offer a great balance between durability and sharpness. Solid carbide bits are also highly durable and provide excellent cutting precision, but they're often more expensive than their carbide-tipped counterparts. For tougher materials or for projects that require a high level of detail, investing in solid carbide bits can be worth the cost. High-speed steel (HSS) bits are also available, but they wear down faster and generally don't provide the same level of performance as carbide bits.

Bit size is another critical factor to consider, as it affects the depth, width, and precision of each cut. Smaller bits are ideal for fine detail work, while larger bits allow for faster cutting and more substantial material removal. It's essential to choose the bit size based on the specific needs of your project.

For best results, don't overlook the importance of feed rate and speed. Each bit has an optimal cutting speed, and operating outside this range can lead to overheating, which will dull the bit faster and may even burn the wood. Different wood types also respond differently to various speeds, so testing on scrap pieces is a good way to determine the ideal settings for each project.

Lastly, keeping your CNC router bits sharp and well-maintained can extend their life and improve performance. Sharpening carbide bits requires special diamond-coated sharpening tools, so it's often simpler to replace dull bits rather than attempt to sharpen them at home. Regular cleaning and proper storage also help to prevent resin buildup, which can impact the quality of your cuts.

Investing in the right CNC router bits for woodworking will undoubtedly enhance your projects, enabling you to create pieces with greater precision and beauty. By understanding the specific purposes and characteristics of different bit types, materials, and sizes, you'll be well-equipped to choose the perfect bit for every task. With the right router bits, your woodworking possibilities are virtually limitless, allowing you to bring intricate designs and detailed carvings to life with ease and confidence.